As part of my Manufacturing and Production Master's class at Parsons School of Design, I conducted a comprehensive sustainability assessment of Uniqlo for my final project. I genuinely enjoyed diving deep into finding efficient and real life sustainability solutions for Uniqlo while taking into consideration ROI. For the final project, we were asked to write a detailed report as well as present our findings in 7 minutes to class. The presentation design was another element of this project that I put my heart and soul into. I channeled my graphic design skills and designed a presentation that aligns with Uniqlo’s branding system while also adding my own creative touch to make the visuals more engaging and dynamic.

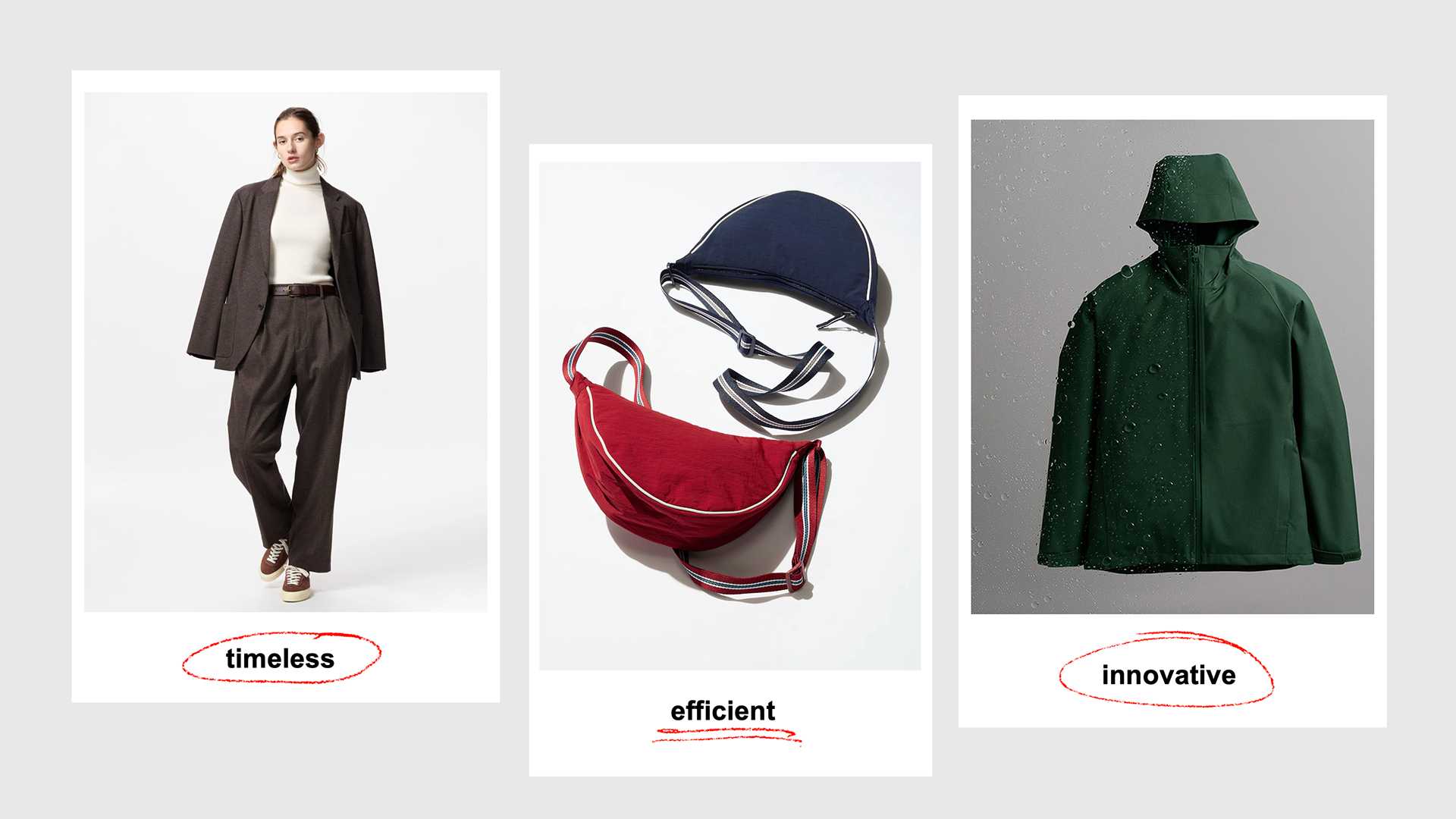

When talking about Uniqlo it’s only fair to mention the brand’s identity which is built on three key pillars: Innovation, Efficiency, and Timelessness. These principles are not just about design and functionality, they also shape the way Uniqlo approaches sustainability. And so any decision or product that Uniqlo embarks on, it needs to ensure that it provides consumers comfort, protection, and pleasure.

Uniqlo's Current Sustainability Goals:

1) Achieve carbon neutrality by 2050

2) transition to 100% renewable energy

3) Ensuring that 50% of its clothing is produced with sustainable materials. These goals reflect the company’s dedication to environmental stewardship and responsible production.

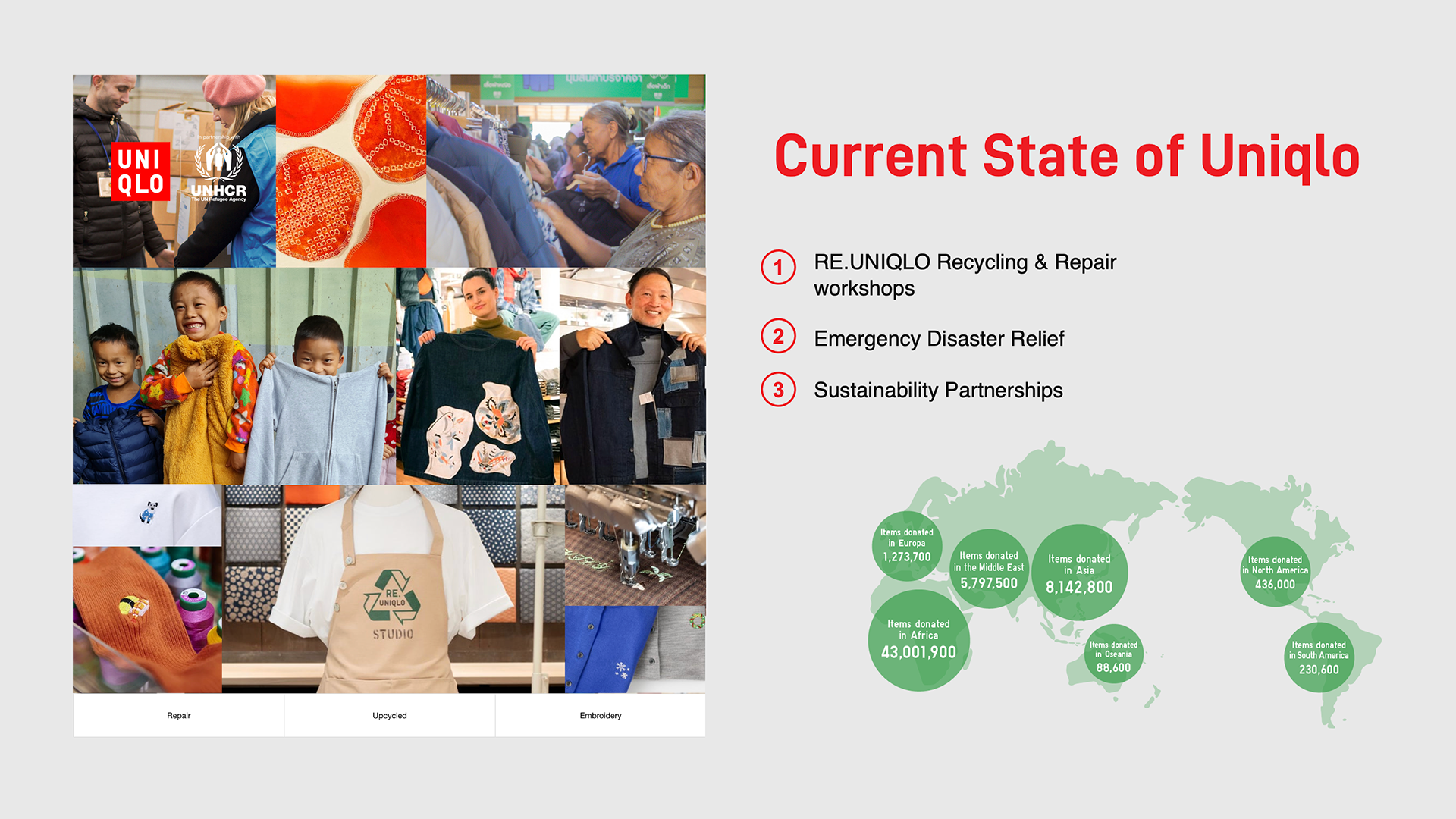

Uniqlo’s Current Sustainability Events:

Uniqlo’s RE.UNIQLO program advances circularity through recycling, repair, and strategic partnerships. The RE.UNIQLO Recycling Program has repurposed nearly 59 million garments for donation and through its Emergency Disaster Relief which ensure that essential garments, such as HEATTECH, are swiftly donated to communities affected by crises. Sustainability Partnerships with innovators like SuperCircle and TORAY strengthen recycling efforts. TORAY helps transform discarded garments into new fibers, while SuperCircle processes unwearable down jackets into reusable raw materials. These initiatives are significant, but integrating circularity across the full supply chain is essential for a truly closed-loop system.

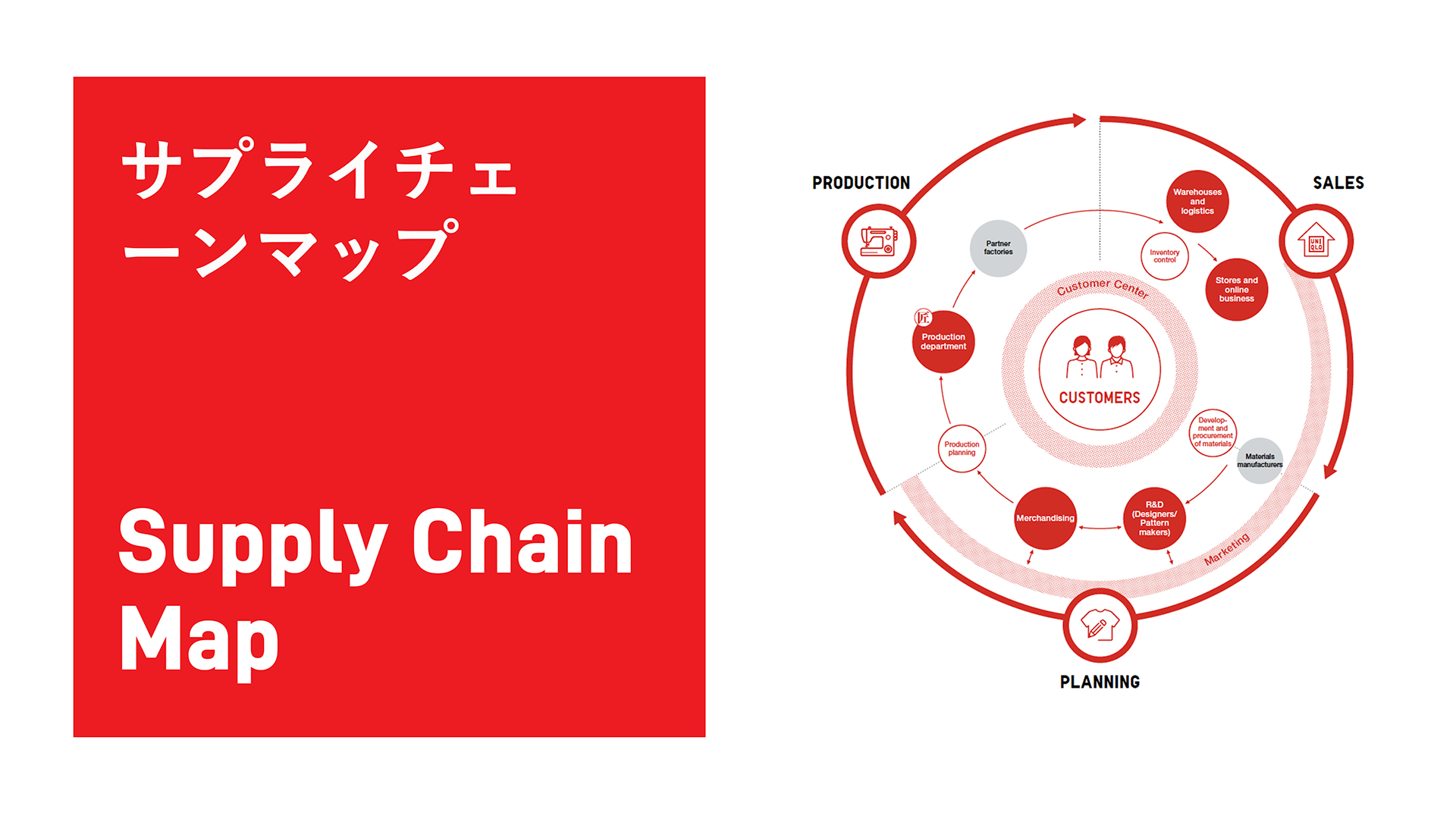

Uniqlo operates a vertically integrated supply chain that enables control over design, sourcing, production, and retail.

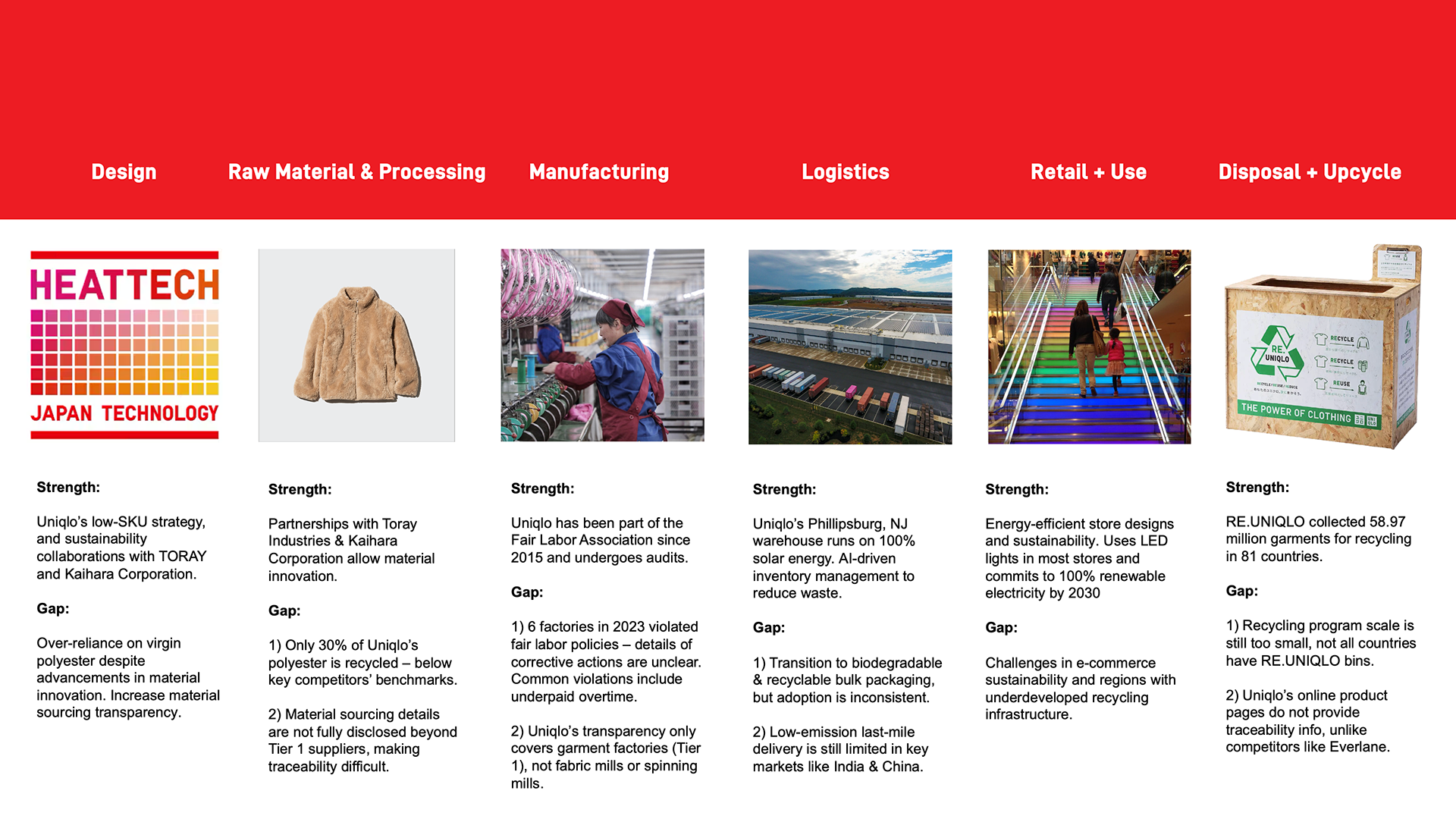

Design

Uniqlo integrates customer insights, trend forecasting, and material innovation into its design process. Its collaborations with Toray Industries and Kaihara Corporation have resulted in high-performance fabrics like HEATTECH (designed to deliver warmth even in extreme cold) and AIRism (comfort conditioning technology).

Despite these innovations, a major challenge is scaling sustainable materials. Currently, only 30% of Uniqlo’s polyester comes from recycled sources, with a goal of reaching 50% by 2030—a target that remains ambitious but still behind its competitors like Everlane, which has already transitioned to 97% certified recycled polyester.

Raw Materials & Processing

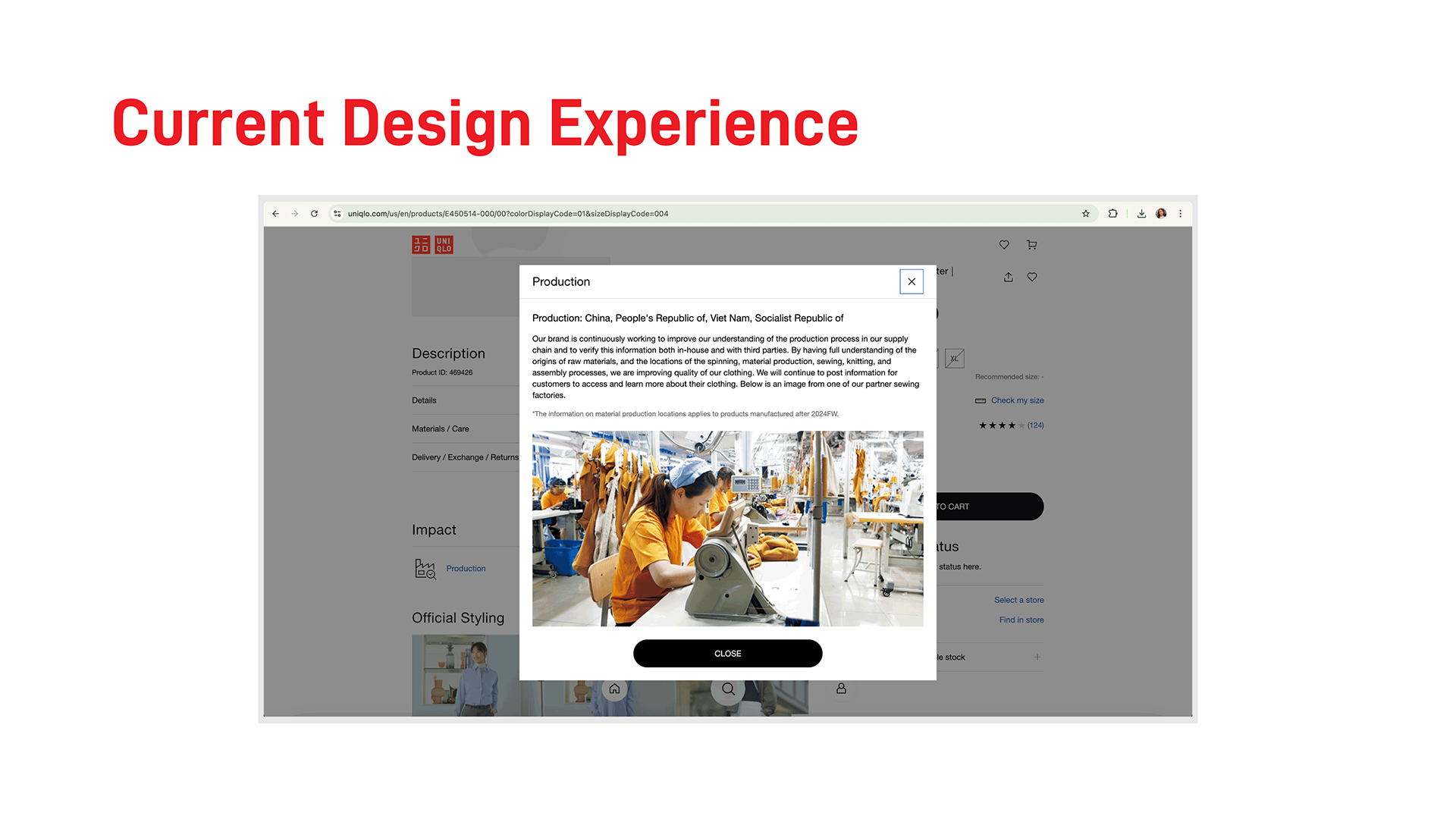

Uniqlo relies heavily on conventional cotton, which is water-intensive and environmentally taxing. Uniqlo also sources raw materials from key suppliers, but transparency remains an issue. While the company publishes a list of its Tier 1 garment factories, information on Tier 2 fabric mills and Tier 3 raw material suppliers remains incomplete.

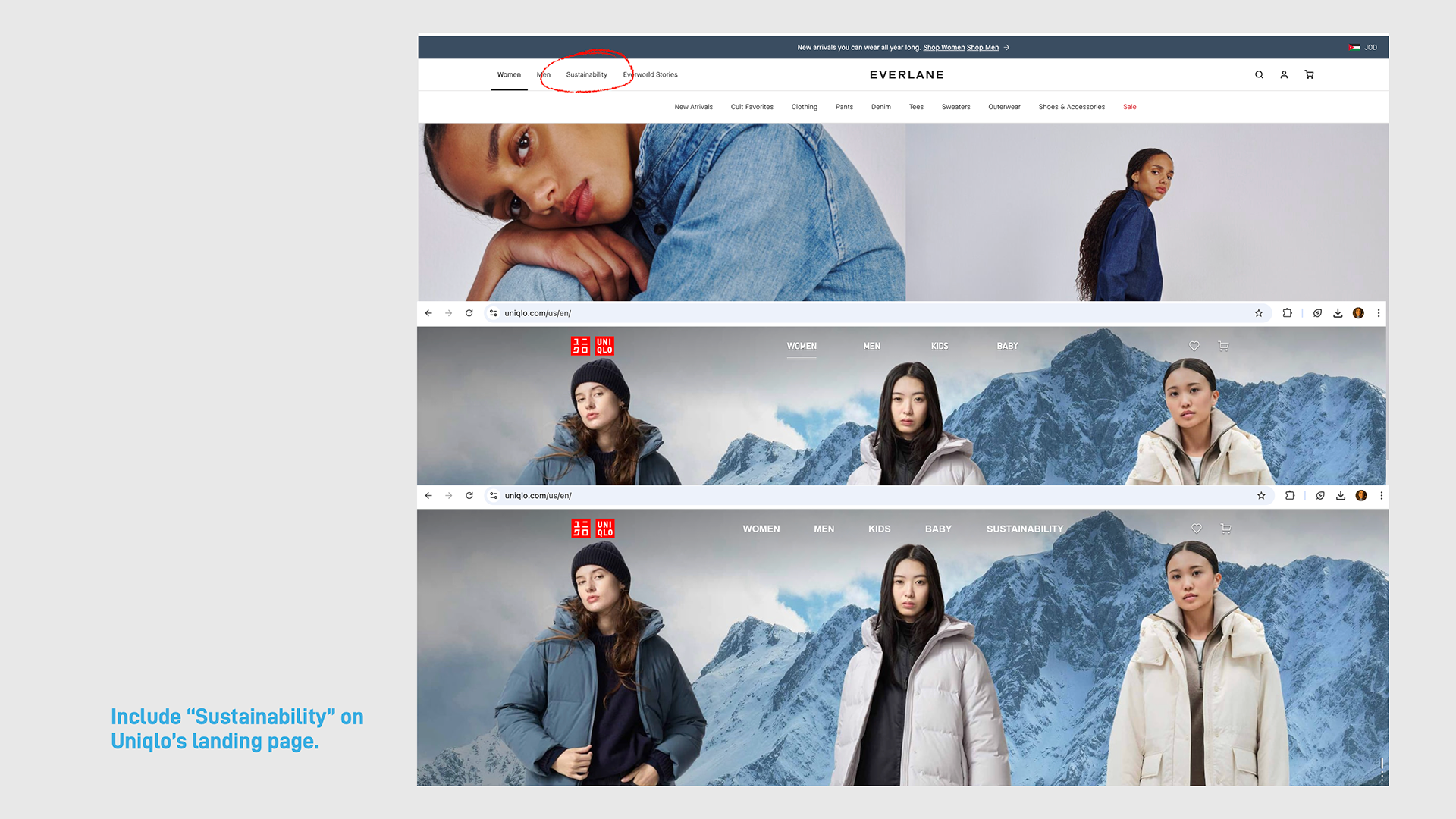

Competitors like Everlane publicly disclose their entire supply chain, including fabric mills and raw material sources, and offer an intuitive website design that consumers and go through for traceability and assurance of ethical sourcing.

Logistics

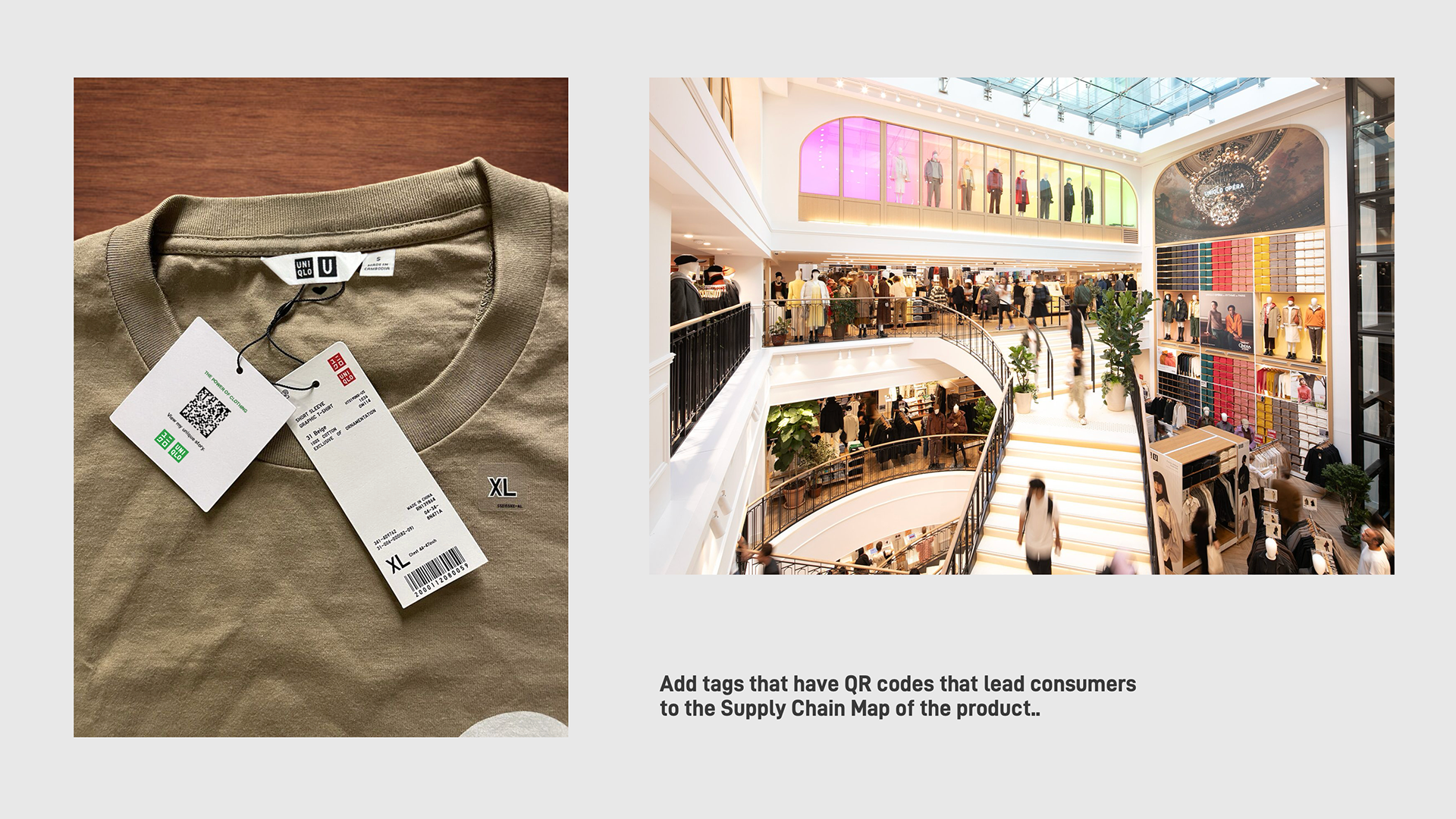

Uniqlo uses AI-driven inventory management through the Ariake Project to reduce overproduction and waste. However, competitors like Everlane and ASOS invest in blockchain-based supply chain tracking, while Uniqlo still lacks real-time traceability tools, making it harder for consumers to verify supply chain sustainability.

Disposal + Upcycling

Uniqlo has partnered with TORAY Industries to develop advanced recycling technologies, especially for down products. The Blue Cycle Jeans project reduces waste by using ozone washing and laser techniques to cut water usage by up to 90% and minimize chemical pollutants. Uniqlo’s SuperCircle partnership helps recycle down jackets, but real-time product lifecycle tracking, as seen with Everlane, is lacking.

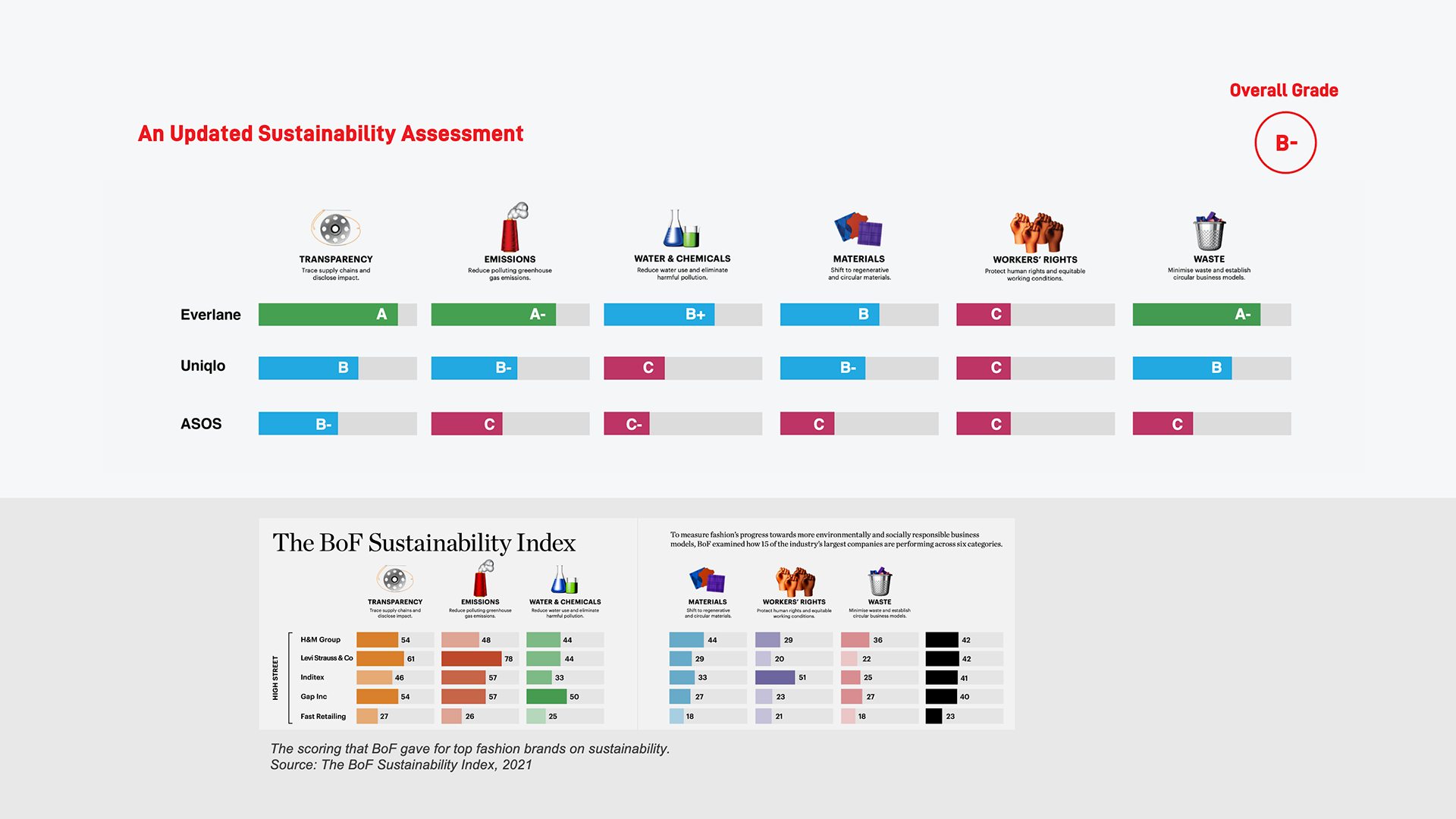

And so, as we can see, Uniqlo has made significant progress across various sustainability efforts. However, challenges in traceability, raw materials processing, and emissions reduction continue to hold the company back from achieving top-tier rankings.

Based on the supply chain journey and the problems identified, Uniqlo scored a B-, especially when compared to the competitive market. Everlane was better overall and ASOS was lower.

As of now, Uniqlo works with TORAY to recycle PET bottles into polyester for products like DRY-EX apparel, but this initiative can be scaled up.

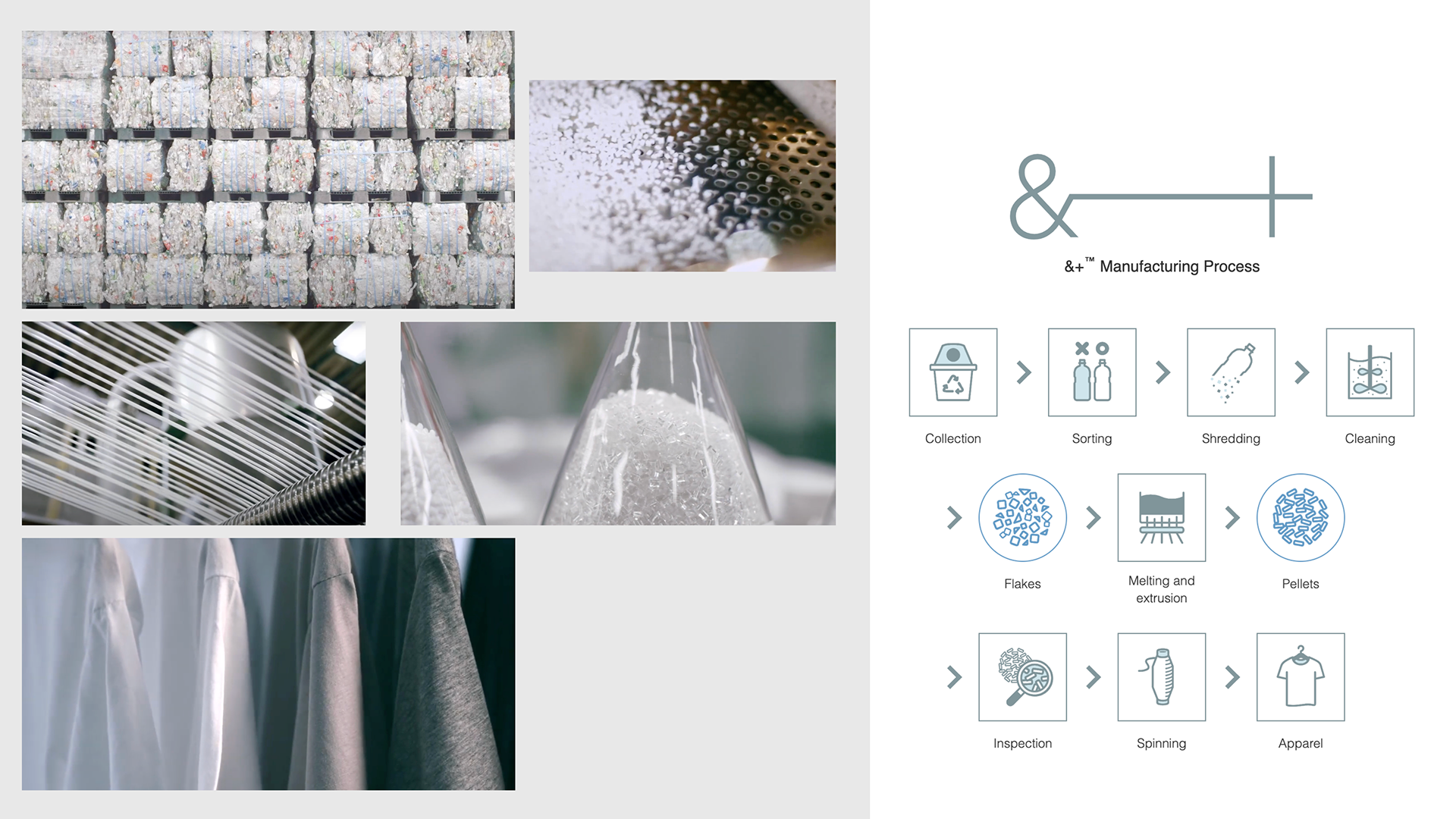

Fiber &+™ is a high-quality recycled polyester fiber made from PET bottles and has several key advantages Fiber &+™ production generates 40% fewer CO2 emissions compared to virgin polyester and TORAY’s process recycles over 1.04 billion PET bottles annually. The recycling process uses 30% less energy than conventional polyester production, supporting Uniqlo’s goal of reducing energy consumption across its operations.

Fiber &+™ is a high-quality recycled polyester fiber made from PET bottles and has several key advantages Fiber &+™ production generates 40% fewer CO2 emissions compared to virgin polyester and TORAY’s process recycles over 1.04 billion PET bottles annually. The recycling process uses 30% less energy than conventional polyester production, supporting Uniqlo’s goal of reducing energy consumption across its operations.

By fully integrating Fiber &+™ into popular product lines like HEATTECH, AIRism, and Ultra-Light Down, Uniqlo can increase its recycled polyester use significantly and support Fast Retailing’s goal of incorporating 50% recycled materials by 2030. Additionally, TORAY’s proprietary Recycling Identification System ensures end-to-end traceability, which aligns perfectly with Uniqlo’s goal of increasing supply chain transparency.

This expansion will not only reduce environmental impacts but also solidify Uniqlo’s reputation as a leader in sustainable fashion innovation

Uniqlo should prioritize investment in research and development of high performance, low-impact materials by collaborating with leading innovation hubs like Material ConneXion Labs. Partnering with Material ConneXion Labs would allow Uniqlo to explore cutting-edge textile solutions such as bioengineered fibers that offer durability, functionality, and reduced environmental impact. By diversifying its material portfolio to include plant-based fibers such as flax and hemp, Uniqlo can significantly decrease its reliance on water-intensive cotton which in return would minimize its environmental footprint.

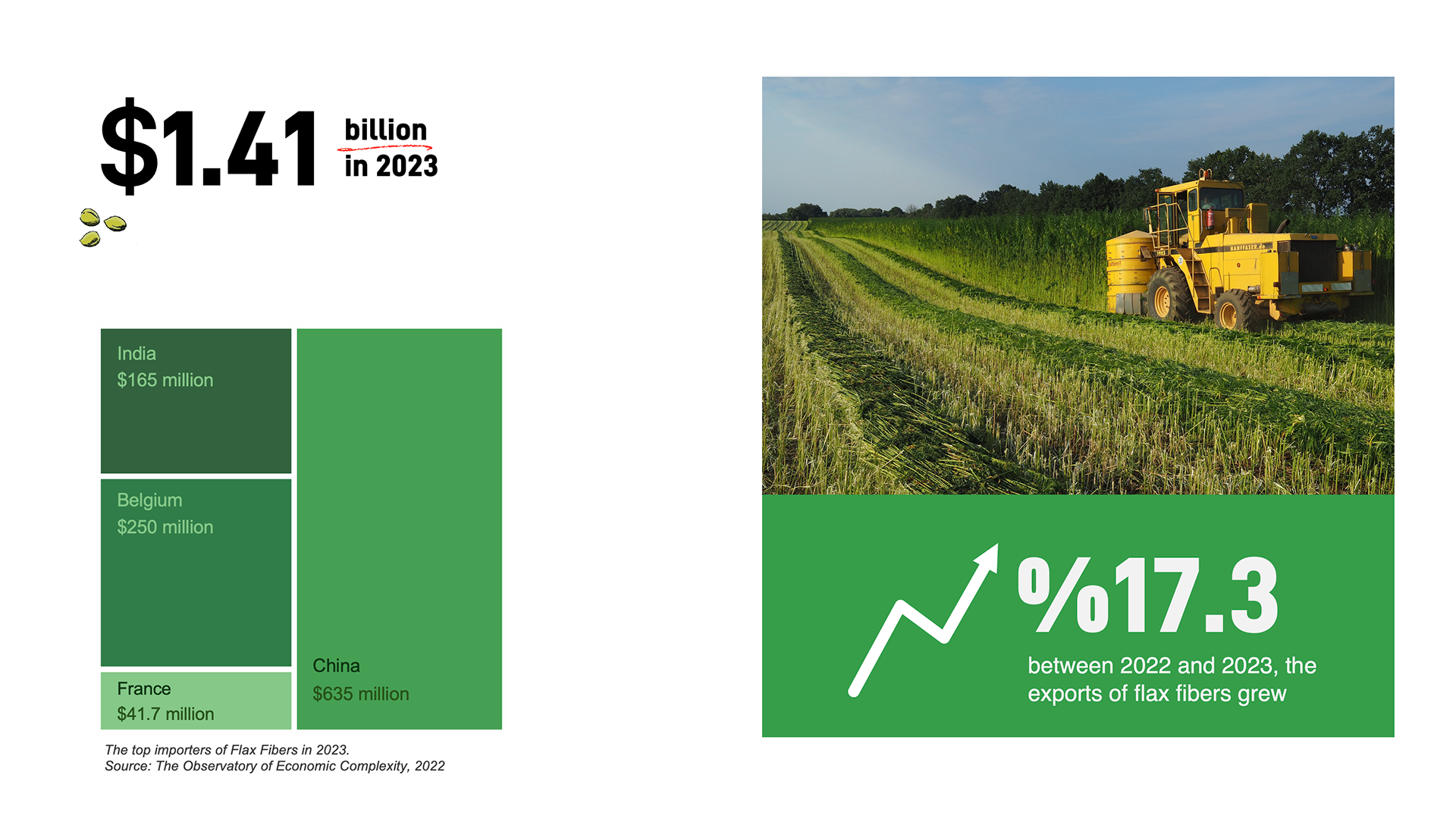

Hemp & flax, which require substantially less water and fewer pesticides than traditional cotton, present viable alternatives. Global flax fiber has become popular. In 2023, Flax Fibers were traded for a value of $1.41 Billion and between 2022 and 2023, the exports of flax fibers grew by 17.3%. This reflects the fashion industries focus on finding alternatives and on flax fibers success so far in supporting those goals. In 2023 the top importers of Flax Fibers were China , Belgium , India, and France. (oec.world) Thus, the availability of this sustainable resource poses a great alternative for Uniqlo to consider for its products. Based on the data sheet that can be uploaded via Fast Retailing’s website, 138 garment factories are located in China while 19 are in India. That said, it is worth reaching out to these factories to pilot and scale the use of flax fibers in Uniqlo’s product lines. The brand can leverage its already existing supplier relationships and facilitate smoother integration of sustainable materials. And so Integrating these sustainable materials into Uniqlo’s product lines would support Uniqlo’s 2030 goal of increasing recycled and sustainable materials to 50%.